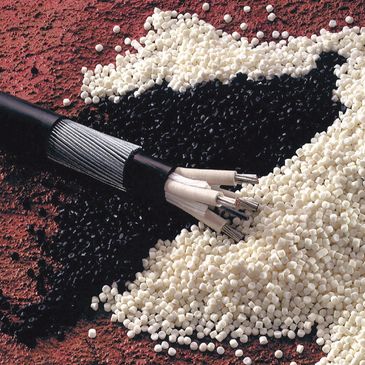

Insulation Compounds

PVC Insulation Compound

PVC Insulation Compound

PVC Insulation Compound

- Thermoplastic compound offering good mechanical strength and flame resistance.

- Dielectric Strength: >18 kV/mm; Temp: up to 70 °C; RoHS compliant

XLPE Compound

PVC Insulation Compound

PVC Insulation Compound

- Cross-linked polyethylene for enhanced thermal stability and low dielectric loss.

- Temp Rating: 90–105 °C; Volume Resistivity: >10¹⁴ Ω·cm

TPE Compound

PVC Insulation Compound

Low Smoke Halogen-Free (LSHF)

- Thermoplastic elastomer for flexible, low-voltage insulation applications.

- Flexibility: High; Temp Range: -40 °C to 105 °C

.jpg/:/cr=t:31.86%25,l:0%25,w:100%25,h:65.2%25/rs=w:365,h:365,cg:true)

Low Smoke Halogen-Free (LSHF)

Get in Touch with Ingreda Experts?

Low Smoke Halogen-Free (LSHF)

- Safe insulation for public buildings and tunnels; limits toxic gas in fires.

- Halogen Content: <0.2%; Smoke Density: Low; Flame Retardant

Silicone Rubber Compound

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

- High-temperature and highly flexible insulation for specialty cables.

- Temp Range: -60 °C to 200 °C; Weather Resistant

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Sheathing Compounds

PE Sheathing Compound

LSHF Sheathing Compound

LSHF Sheathing Compound

- Polyethene-based compound providing toughness and moisture resistance.

- Density: 0.92–0.94 g/cm³; Temp Range: -40 °C to 70 °C

LSHF Sheathing Compound

LSHF Sheathing Compound

LSHF Sheathing Compound

- Halogen-free compound designed to reduce smoke and toxic gas emissions in fire.

- Halogen Content: <0.2%; Flame Retardant; Low Smoke Density

TPU Sheathing Compound

LSHF Sheathing Compound

TPU Sheathing Compound

- Thermoplastic polyurethane offering abrasion resistance and flexibility.

- Tensile Strength: >40 MPa; Temp Range: -50 °C to 105 °C

PVC Sheathing Compound

Get in Touch with Ingreda Experts?

TPU Sheathing Compound

- Flexible sheathing compound with good weather and oil resistance.

- Dielectric Strength: >15 kV/mm; Flame Retardant Grades Available

Neoprene Sheathing Compound

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

- Rubber-based compound providing oil, chemical, and weather resistance.

- Temp Range: -40 °C to 90 °C; Resistant to oils and fuels

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Flame Retardants

Aluminum Trihydrate (ATH)

Aluminum Trihydrate (ATH)

Aluminum Trihydrate (ATH)

- Widely used inorganic FR filler for cable compounds; decomposes to release water vapour.

- Decomposition Temp: ~200 °C; Particle Size: 1–50 µm; Non-toxic

Magnesium Hydroxide (MDH)

Aluminum Trihydrate (ATH)

Aluminum Trihydrate (ATH)

- High-temperature flame retardant releases water to suppress fire and smoke.

- Decomposition Temp: ~330 °C; Particle Size: 1–20 µm; Low smoke

Halogen-Free FR Systems

Aluminum Trihydrate (ATH)

Halogen-Free FR Systems

- Formulated blends of mineral fillers and polymers for safe, eco-friendly FR performance.

- Halogen Content: <0.2%; Compliant with RoHS/REACH

Phosphorus-based FRs

Get in Touch with Ingreda Experts?

Halogen-Free FR Systems

- Reactive and additive flame retardants improving char formation in cables.

- Phosphorus Content: 15–20%; Halogen-Free; Synergistic with ATH

Nitrogen-Phosphorus Synergists

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

- Advanced FR systems combining P/N for smoke suppression and char stability.

- Intumescent effect; Eco-friendly; Improved flame retardancy

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Conductive Compounds

Semiconductive Shielding Compound

Semiconductive Shielding Compound

Semiconductive Shielding Compound

- Carbon black-filled PE/XLPE used in cable shielding layers.

- Resistivity: <500 Ω·cm; Smooth extrusion; Compatible with XLPE

Bonded Shield Compounds

Semiconductive Shielding Compound

Semiconductive Shielding Compound

- Semi-conductive layer bonded to insulation for cable integrity and stress control.

- Volume Resistivity: <1000 Ω·cm; Strong adhesion to insulation

Strippable Shield Compounds

Semiconductive Shielding Compound

Strippable Shield Compounds

- Semi-conductive material allowing easy removal during cable termination.

- Resistivity: <1000 Ω·cm; Peel strength optimized; Easy strip design

Conductive PE Compounds

Get in Touch with Ingreda Experts?

Strippable Shield Compounds

- Polyethylene compounds with conductive fillers for grounding and antistatic layers.

- Surface Resistivity: 10³–10⁵ Ω/sq; Tensile Strength: >12 MPa

Conductive EVA Compounds

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

- EVA-based conductive blends for flexibility and shielding in special cable applications.

- Volume Resistivity: <10³ Ω·cm; Flexible; Good processability

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Stabilizers & Additives

Heat Stabilizers

Antioxidants (Primary)

Heat Stabilizers

- Additives that protect cable polymers from thermal degradation during processing/use.

- Based on Ca/Zn or organotin; Effective up to 200 °C

UV Stabilizers

Antioxidants (Primary)

Heat Stabilizers

- Absorbers and quenchers prevent UV-induced cracking and discolouration.

- Hindered Amine Light Stabilisers (HALS); Long-term outdoor stability

Antioxidants (Primary)

Antioxidants (Primary)

Antioxidants (Secondary)

- Radical scavengers prevent polymer oxidation under heat and stress.

- Phenolic-based; Effective at 0.1–0.5% loading

Antioxidants (Secondary)

Get in Touch with Ingreda Experts?

Antioxidants (Secondary)

- Peroxide decomposers and synergists extend the thermal resistance of insulation.

- Phosphite-based; Work with phenolics for enhanced durability

Processing Aids

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

- Lubricants and modifiers improve extrusion, dispersion, and surface finish.

- Stearates, waxes, or siloxanes; Reduce melt viscosity; Improve output

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Get in Touch with Ingreda Experts?

Proudly Canadian Business 🍁

Copyright © 2025 Ingreda Canada - All Rights Reserved.

Powered by Ingreda Canada

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.